ION to process black mass into battery metals as part of EU consortium

Our recycling Investment IonDrive (ASX: ION) is now testing its DES (Deep Eutectic Solvents) tech in the battery metals supply chain inside Europe…

More on how ION’s tech works later in today’s Quick Take.

ION confirmed today that it would be participating in the battery recycling consortium led by German PEM RWTH Aachen University, which has to date received ~€2.07M in EU grant funding.

The consortium will spend ~€3M (with contributions from the consortium members) looking to show that battery cells made from 80% sustainably recycled materials can perform on par with those using virgin metals.

ION’s role in the consortium is to show that it can process black mass (waste batteries) into high-purity battery-grade metals using its environmentally sustainable DES method.

And then to see if ION’s tech can help convert the materials into useful pCAM (Precursor cathode active materials) that go into the batteries.

The ultimate aim is to show that the batteries can perform at a level that would potentially be suitable for use in cars…

The announcement today mentioned that the “consortium has engaged with leading European automotive OEMs and battery manufacturers, who are expected to become actively involved following the achievement of key technical milestones”

So any good news from the work being done as part of the consortium could translate into one of the big European carmakers coming into the consortium.

We already know ION’s tech is able to recover nickel, cobalt, lithium and manganese from black mass (all of which are key inputs into batteries).

(Source)

Now we just need to see those recovered materials perform in battery cells to a level that the automakers start to show interest.

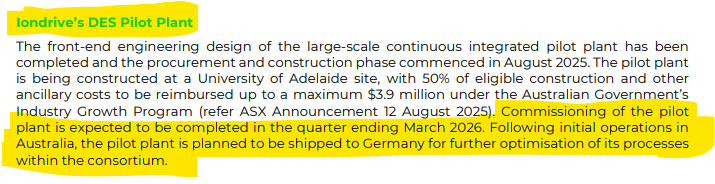

We also noticed in today’s announcement, ION’s plan is to move its pilot plant to Germany for all of the more advanced testwork to be completed by the consortium in the future.

ION’s pilot plant is currently under construction and ION expects to have it commissioned in the first quarter of next year.

(ION’s plant is being constructed with Australian government funding for 50% of the build costs - up to A$3.9M - we covered that news here).

(Source)

Who else is part of the consortium ION is working with?

Founding members and their roles include:

- Accurec Recycling GmbH – provides expertise in battery dismantling and mechanical processing to produce black mass.

- Iondrive EU GmbH (the German entity of ION) – processes black mass into high-purity, battery-grade metals and pCAM materials (Precursor cathode active material) using its DES technology; its pilot plant in Australia will be shipped to Europe by mid-2026.

- NEUMAN & ESSER Process Technology GmbH – contributes process engineering and equipment for scaling recycling operations.

- Constantia Patz GmbH – brings expertise in recyclable materials and sustainable manufacturing integration.

- PEM RWTH Aachen University – will convert Iondrive’s pCAM into CAM material for use in battery cell manufacturing.

PEM (Production Engineering of E-Mobility Components) is a research chair/department arm within RWTH Aachen University, the co-founder of this was also the co-founder of StreetScooter, an electric vehicle manufacturer.

Interestingly StreetScooter was originally developed as a project at RWTH Aachen before being spun out, perhaps there is a similar plan here…

The goal then was to develop an affordable electric vehicle tailored for short-distance urban deliveries, with that project involving collaboration with over 80 medium-sized companies and research institutions.

How does ION’s tech work?

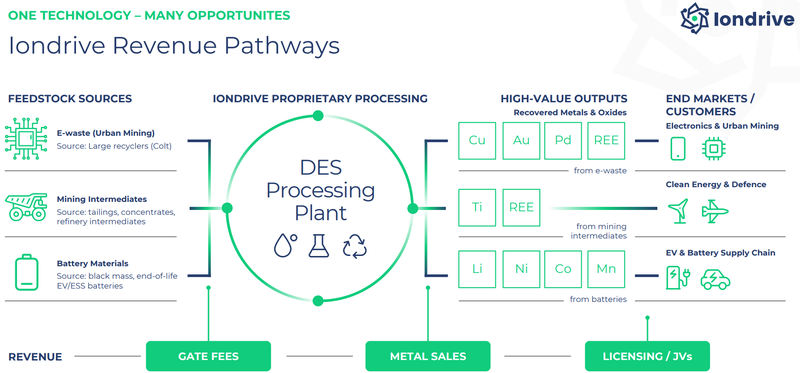

ION’s potential breakthrough technology has already shown at lab scale that it can produce very high recoveries of the following metals:

(Source)

(Source)

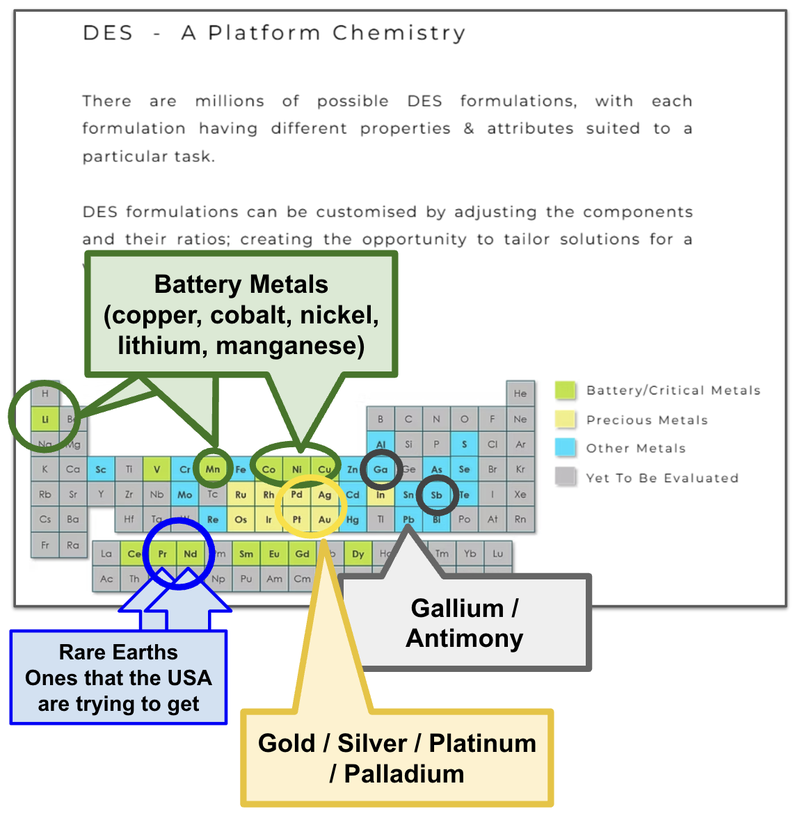

Below is a larger list of metals that Deep Eutectic Solvents (which ION uses in its IP protected processing technology) have been tried and tested on in metals extraction and recycling - we’ve highlighted some of the key critical metals:

(Source)

Note: this chart shows metals amenable to Deep Eutectic Solvent chemistry in general, and have not necessarily been specifically tested by ION.

What’s next for ION?

Over the next 6-9 months, we think one (or multiple) of the below catalysts could trigger a sustained re-rate in ION’s market cap:

- US rare earths partnership - ION will now test its tech on e-waste feedstock to see if it can commercially recover rare earths. IF successful, ION’s tech could be rolled out across recycling facilities processing ~40M lbs of e-waste feedstocks annually.

- Pilot plant build for battery recycling tech - as mentioned prior, we think this will be a big inflection point for ION. ION expects to have the plant built and commercially producing by “early 2026”.

- EU consortium progress - The consortium now has over €3M committed to trying to build battery cells using recycled battery metals from black mass (waste batteries). The consortium is partly funded by an EU grant of ~€2.07M.

- ION’s mineral processing tech gets de-risked - ION is currently testing its technology on “US sourced feedstock”. Any big feedstock supply deal, partnership deal or any strong recovery results could be a big unexpected catalyst for ION.

- Application into new markets - Here, ION is looking at recovering copper, gold, silver, osmium and rare earth elements from e-waste (Printed Circuit Boards). Results from these tests could come at arbitrary times. We could see the market re-rate ION if the results are positive.

- Graphite upgrade results - updates on this front came from a recent ION’s announcement. If ION can produce anode-grade graphite from recycled black mass, it could add to the economics of its pilot plant and strengthen the commercial case for a bigger plant. See our Quick Take on that news here.

- Testing on EU cobalt deposit - ION has signed a deal with ASX listed Latitude 66 to test its tech on the company’s cobalt project in Finland.

Here is a nice slide from ION’s latest presentation that summarises everything that is coming:

(Source)